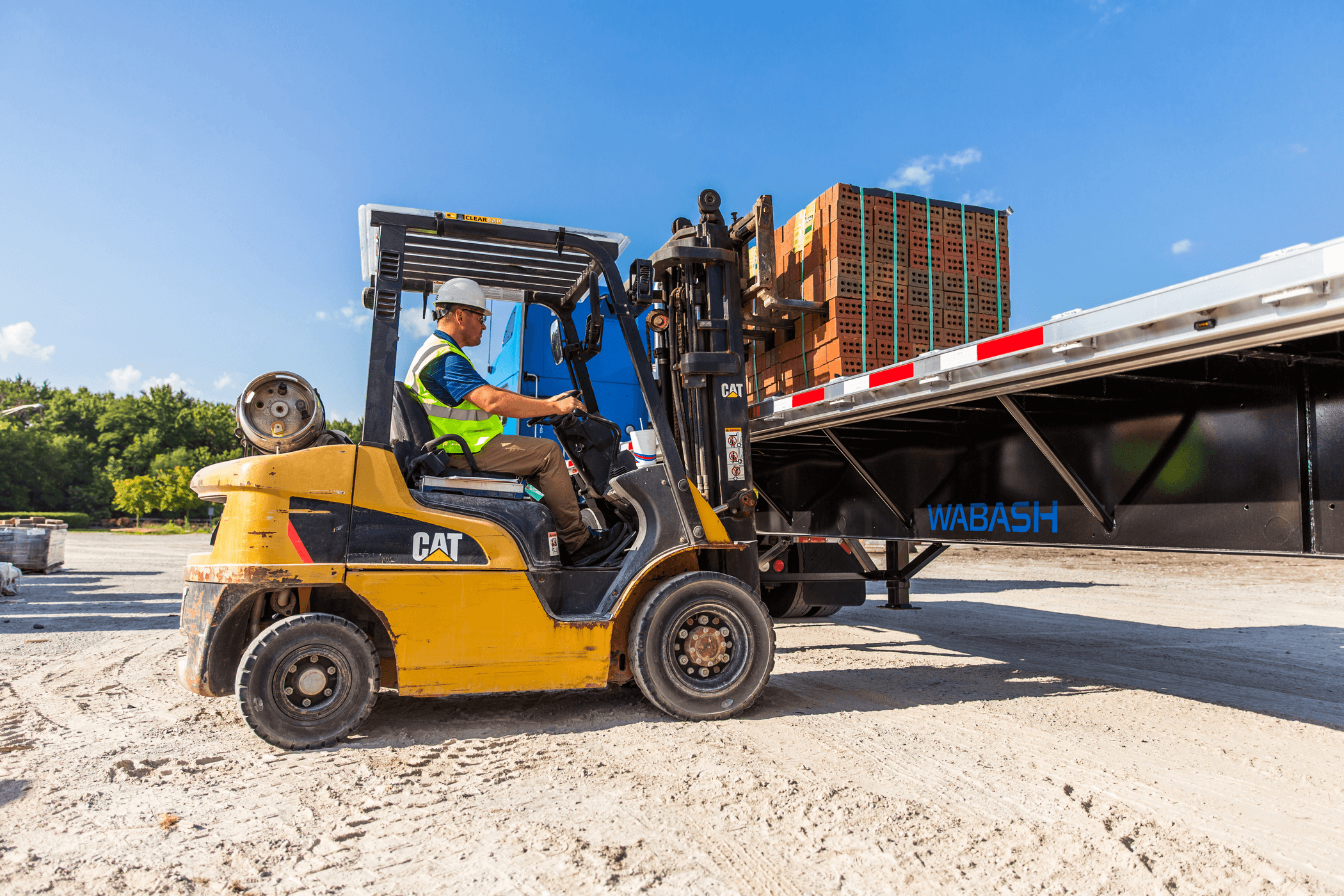

The Combo Flatbed That Changed Everything

Wabash Combo Flatbeds

Premium Toughness Comes Standard.

• Rugged, heat-treated 130ksi steel construction available in flatbed or dropdeck configurations.

• Strategic welds eliminate corrosion between the flange and web.

• “K”-type structural assembly reduces side bending and flex.

• Double-shear flooring connection minimizes racking and nailer damage for long-term durability.

Designed for Uptime.

• Bolt-on, integrated winch track side rail simplifies repair and replacement.

• Flexible Lock-Rite® II multi-position tie-down system accommodates various load types.

• Includes a standard 5-year wheel-end warranty for peace of mind and reduced downtime.

Better Highway Visibility.

• Enhanced lighting system includes three stop/tail/turn lamps and five dual-function side markers.

• Side marker lights also function as turn signals, improving motorist visibility and highway safety.

Superior Corrosion Resistance.

Every steel surface is 100% shot-blasted prior to primer and paint—no chemical pretreatments needed. From ultra high-zinc epoxy primer and galvanic coating to automotive-grade acrylic urethane paint, expect superior corrosion resistance and higher resale value.

Combo Flatbed Trailer Specifications

| Category | Details |

|---|---|

| General | Length: 28′–53′ Width: 96″ and 102″ |

| Beam Ratings |

554: 55,000 lb in 4′ / 60,000 lb in 10′ / 93,700 lb evenly distributed 654: 65,000 lb in 4′ / 70,000 lb in 10′ / 110,400 lb evenly distributed 734: 73,000 lb in 4′ / 80,000 lb in 10′ / 125,000 lb evenly distributed |

| 48′ Base Weights |

554: 9,896 lb 654: 10,099 lb 734: 10,686 lb |

| Main Beam Design |

• Fully welded flange and web joints • 50,000 PSI steel web • Automated continuous weld • 130,000 PSI heat-treated flanges • 24″ cross braces, 48″ knee braces |

| Front End Design |

• Fabricated aluminum front crossmember • Center mount glad hands & 7-way on access panel • ¼″ steel coupler plate, SAE J133 tested |

| Rear End Design |

• Three integral stake pockets • Horizontal bumper end caps • Vertical rubber dock bumpers (3-bolt) • DOT and Transport Canada compliant |

| Siderail Design |

• Bolt-on, integrated winch track (6061-TX aluminum) • Radius edges, recessed rub rail • Stake pockets on 24″ centers • Lock-Rite II tie down system • Large double pipe spools |

| Crossmembers & Floor |

• 80K tensile 4″ steel “I” beams on 12″ centers • Mylar gaskets between aluminum/steel • Aluminum + wood floor boards • 1-1/8″ aluminum floor boards + apitong nailers • 2 grade-8 screws per crossmember • Optional: 5″ aluminum crossmembers |

| Undercarriage |

• Widespread K-bracing, angular gussets • Suspension support with truss design • 121″ tandem widespread axle • “P” spindle wheel ends, alignment, large bearings |

| Electrical / Lights |

• Access via aluminum front plate • Below-deck routing • LED visibility system, 5 marker lights per side • Dual function marker/turn signals • ABS braking system |

| Finish & Prep |

• 100% shot blasted prior to assembly • No chemical pretreatment needed • High-zinc epoxy primer + galvanic coating • Acrylic urethane topcoat • Automotive-style badging |

| Popular Options |

• Additional air/electric configs • Extra aluminum parts • Coil/floor packages • Alternate crossmember spacing • Custom bumper plates • Factory bulkheads • Axle configs, lift/sliding suspensions • Storage + freight securement accessories |

| Warranty |

• Lifetime on main beam • Standard 5-year on P-spindle wheel ends |